How to Install Asphalt Shingles

Shingles are an important part of your home that protects you from the elements, and it is also a job you can do yourself. Moreover, if you take on the installation personally, you stand to save both time and money. All you have to do is follow the same steps a pro would, and you can end up with a roof every bit as appealing and effective.

That being said, doing things the right way is vital to adding new shingles or re-roofing your home. The steps are few, but they are important. It starts with preparing the roof, which includes removing the old shingles. Then, you will install the three-tab shingles, followed by the ridge shingles.

Prepare the Roof

Planning and prep work are both necessary to ensure you do not waste time or money later down the line. That includes determining and buying the right number of shingles and measuring the length of the shingles. You will then want to remove the old, tidy things up, and get started on the underlayment and flashing. After that, all that you have left is the installation of a starter course and the shingles.

Purchase the Right Number of Shingles

You need to purchase the right amount of shingles to get the job done, which means you need to know the dimensions of your roof. A good rule of thumb is three bundles of shingles per 100 square feet, though you will want to get an additional 10% of materials to cover potential wastage.

Do not be confused about the idea of bundles, which comes from the wooden counterpart. The shingles will come in packages, which you can purchase as you would bundles.

Additionally, while there are more detailed guides to measuring your roof, you can do it quickly by going section by section. First, get the length and width of each section, then multiply them together. Next, add all of the areas together and divide by 100 to get the necessary squares. Finally, multiply that by three to determine the number of bundles needed.

Measure the Shingle Length

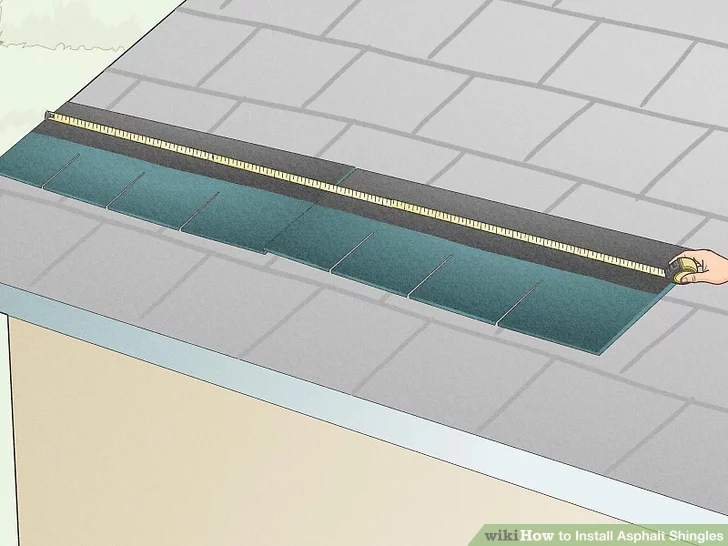

Measuring the length of a shingle after laying it across the roof will offer perspective that will let you know how they are going to go down. A majority of asphalt shingles are around three feet long, and it is unlikely there will be a perfect fit across the roof. That means partial pieces, which means cutting that you need to plan. Additionally, the bottom row needs to be left hanging past the edge.

Remove the Old Shingles and Flashing

Removing the shingles and flashing is an important step that you want to do carefully. It is best to start at the peak, doing so at the corner furthest away from whatever you are using for debris disposal.

Once you pick a spot, use a garden fork or roofing shovel and begin pulling them off. Just make sure that you protect your home while working, such as windows, which could break if you are not careful. Try leaning a piece of plywood against the home below where you are working, which will help you protect the siding and windows.

As for the metal flashing around chimneys, vents, and valleys, it is a good idea to just get rid of it while you are up there working. It is okay to keep flashing that is in good shape, but the majority of roofers will get rid of it and start anew, especially when it comes to the flashing in the valleys.

Tidy the Roof

When you were removing the old shingles, you should have been getting all the nails along the way, but if you did not, it is fine. Now is your chance to clean everything up, sweeping the roof and prying up any remaining nails. You will also want to take the chance to take care of loose boards and check for damage, replacing any problem sections.

Install the Underlayment and Flashing

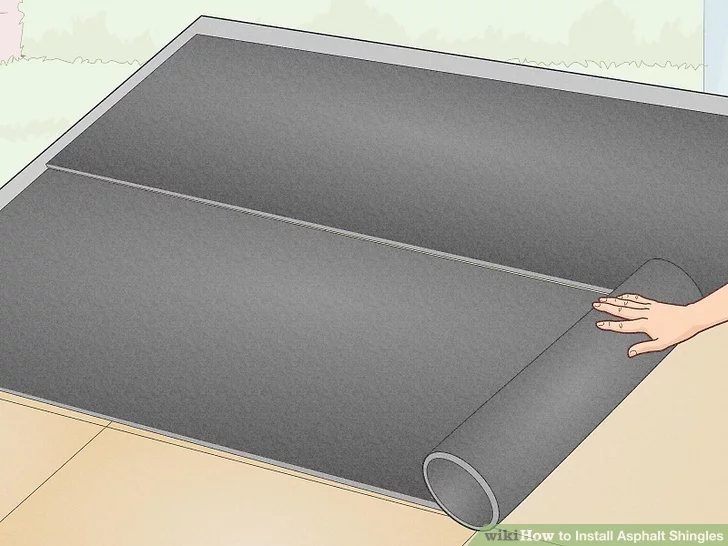

There are multiple types of underlayment you can use, including asphalt, felt, and special waterproof underlayments. Common underlayments include 15-pound roofing paper or a self-sealing membrane with a rain screen, but it depends on what you need. Regardless, the installation follows a similar pattern.

Start low and work upward, stapling the underlayment down as you go. Be generous with the staples while being careful to avoid tears. Also, there should be a 3-inch overlap for each row. If there is a chance the roof will experience wind prior to the shingles going down, use “tin caps” beneath the staples.

You might also consider using sticky back ice and water shield in certain areas. Particularly, you want to do this where ice dams and leaf and twig dams are likely. It is also a good choice for valleys where the roof ends at a wall.

At the same time, you will want to put down new flashing, such as a drip edge, which runs along the bottom edge of the roof deck. Rake edge flashing for the sides of the roof is also necessary. Lastly, take care of the flashing around each chimney and wall, known as step and turn back flashing.

Decide on a Starter Course

The starter course gets you started, and there are a few ways to go about it. One option is purchasing starter shingles, but you can also cut your own to suit the project. The latter allows you to purchase a single type of shingle, though it is not quite as easy as the pre-cut variety.

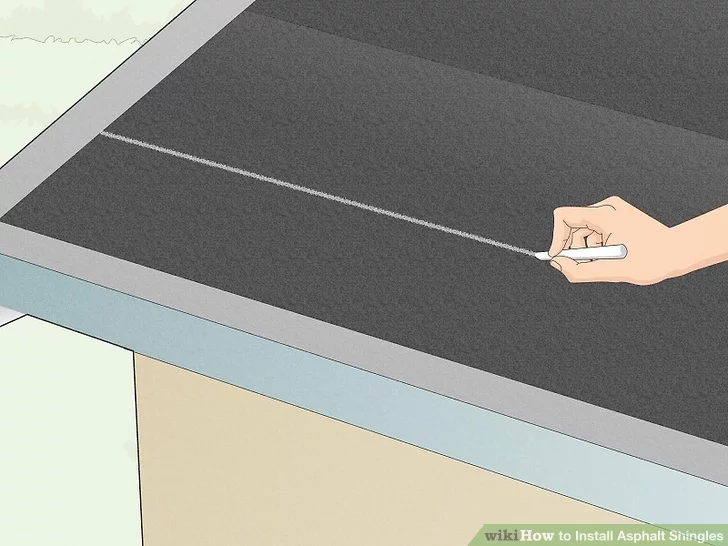

Mark Out a Guide Using Chalk

With your starter course decided, get chalk to mark out a guiding line. While this is not a mandatory step, it can be helpful to mark a line beginning seven inches from the bottom of the roof, though the exact distance will depend on the roof and shingles.

Mark from edge to edge, creating lines that will be visible above each course, acting as guiding lines. Create more lines based on shingle width through a minimum of four courses (rows) across the entire roof.

Install Three-Tab Shingles

With all of the prep work out of the way, it is time to begin laying down shingles. While the process has a bit of involvement, it is not difficult once you have a grasp on it. It all starts with the starter shingles, followed by cutting shingles for staggering slots. From there, all you have to do is lay down each course and cut any excess material.

Take Care of the Starter Shingles

As previously mentioned, there are a few ways to go about dealing with starter shingles. One method is cutting shingles to size, which creates starter shingles by removing the tabbed portion from the three-tab shingles you are using. Once that is done, the shingles can be used as your starter course, which is just the bottom row.

There is still some prep to do, though, which is shortening the first starter shingle by six inches (half a tab). After it is ready to go, place a glue strip along the drip edge and rake edges. Other shingles will go atop the starter shingles, making the first row doubly thick.

Another way to take care of the starter shingles is simply turning the shingles for the starter course, facing the tabs up instead of removing them. While this removes one step, you still want to cut half a tab away to prevent the slots from lining up and exposing the underlayment.

If using shingles without tabs, you will want to nail them down. After, use asphalt cement, dotting beneath the edge of the shingles along the drip edge. The use of dots instead of a single line is important since it prevents moisture from being trapped beneath the roofing. Then, once the cement is in place, press down.

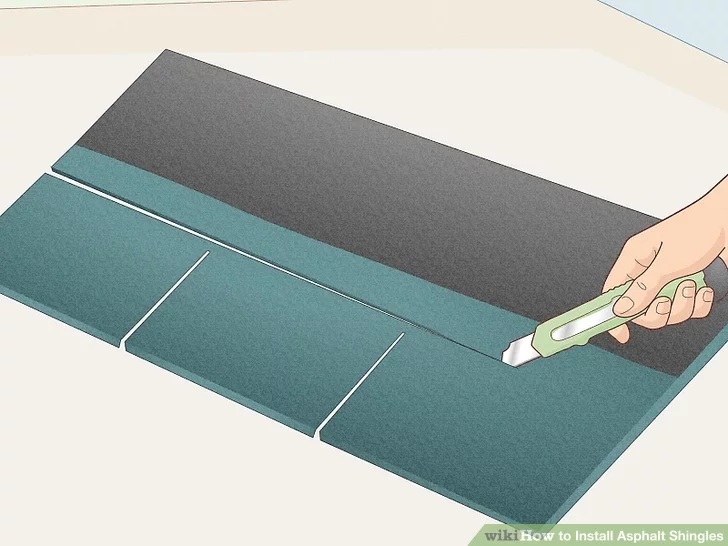

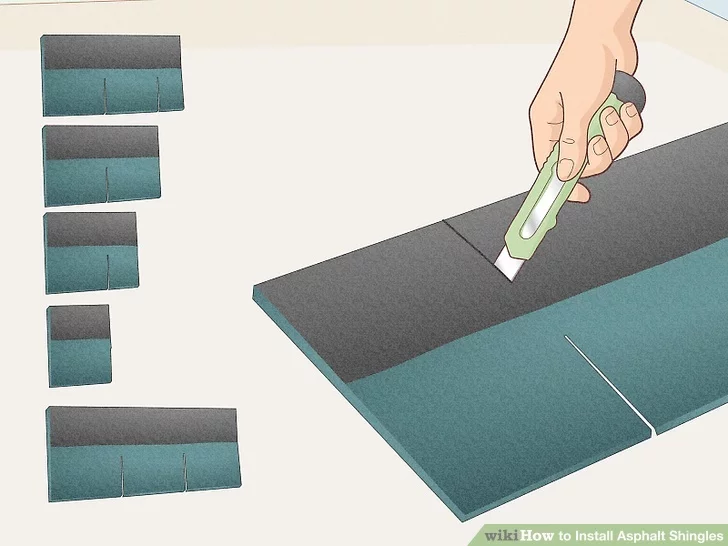

Cut Shingles for Staggering

Staggering the slots is necessary to protect your roof from the elements. It is best to cut multiple sizes using the three-tabs to ensure you have everything you need, starting with cutting half of a tab for the first course. After that, all of the cuts help in shifting the slots by half of a tab, preventing them from lining up with those above and below.

Following the pattern, your first course will have half of a tab removed, while the second will have a full tab removed. The third and fourth courses will have one and a half and two tabs cut off, respectively. For the fifth, you will cut off half of a tab from the last tab. The sixth will remain completely intact.

While it might seem like a lot of wasted material, the good news is that it can be used elsewhere, such as the single-tab cuts for the ridge cap shingles.

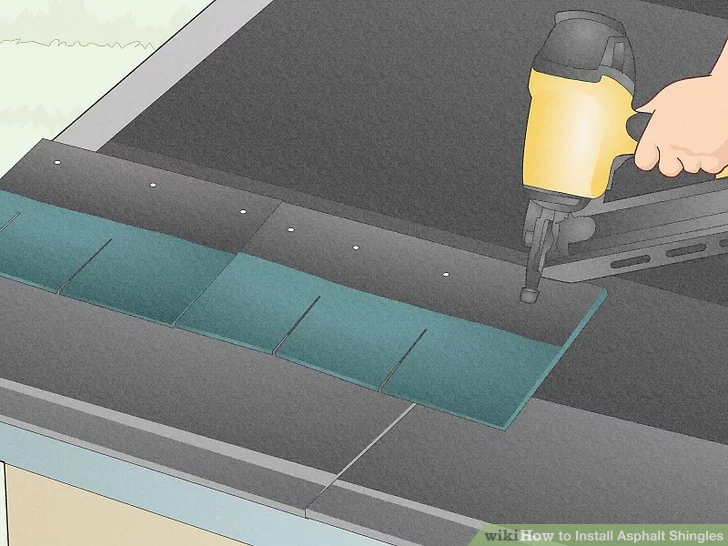

Lay Down Shingles

Each course (row) is about the same, starting with you laying down the cut shingle around six inches from its lower edge. You then hammer in a nail two inches from each end, followed by nails one inch above every slot. Keep in mind that the nails should never hit the tar strip.

By doing things this way, the shingles above will cover the nails by around an inch vertically. The end nails should also be covered by around half of a tab horizontally. Just be sure that the nails hold the top edge of the row below.

With the cut shingle in place, you can start using full shingles, placing them edge to edge and nailing them into place. Use the same method of nailing as you did for the starter course, following the chalk line for guidance to keep things straight.

When nailing shingles using the method of one at each end and one above each slot, you will come out with four per shingle. However, when facing windward, using six nails is a better choice. In fact, some local codes will demand six on every side, so it is not a bad idea to do it regardless.

As you lay down your shingles, you might notice they do not fit perfectly on the roof. When you reach the opposite end from where you started, it is likely there will be overhanging material. Simply nail the shingle down and then cut the excess material, making sure it is nice and neat before repeating the process on the next row.

One exception for cutting the excess material is if you are dealing with a hip roof. If you are, leave a tab of overhang at the hip to strengthen the joint.

Install Ridge Shingles

Once you have installed shingles from the bottom to the peak on both sides of the roof, you still need to install the ridge shingles. That means putting down the last course, installing the ridge shingles, and applying a layer of asphalt cement.

Put Down the Last Course

After working your way to the peak on both sides, bend the last course over the ridge to around six inches. Then, nail it down on the other side, extending it over the top of the ridge so that the nails are covered, leaving none exposed.

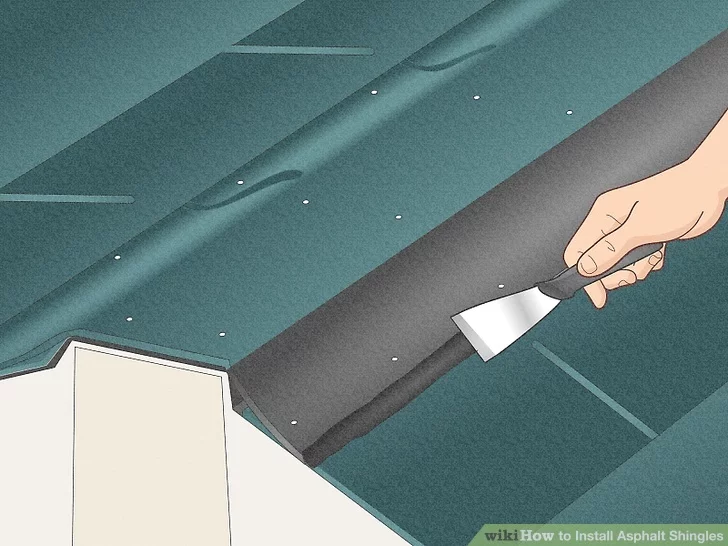

The exception is if ridge vents are going to be installed, which is a common practice. In that case, the sheeting will stop short on both sides. End your final row of shingles at this point and use the hook blade to cut, then cover the ridge by installing vented cap shingles or continuous ridge venting.

Bend single-tab shingles over the ridge or use special ridge shingles. Then, starting at the end, place a bead of asphalt under the first shingle to hold the tab down. After that, nail each shingle so that the next will go over the nails by around an inch.

Install the Ridge Shingles and Apply Asphalt Cement

It is time to install the ridge shingles, which you will do by nailing the shingles on both sides of the ridge like before while the asphalt granules are exposed. Once you are at the other end, cut away the asphalt nail line from a ridge shingle.

Finally, apply a generous bead of asphalt cement, dotting it under and around the edge of the last ridge shingle, which is where you should have removed the nail line. Then, nail the four corners to the end of the ridge, adding a bit of tar to cover the nail heads. You should also apply cement over exposed nail heads on the final shingle to prevent leaks.

With over 12 years of construction industry experience, David Bitan specializes in restoring, inspecting, maintaining, and repairing roofs for residential, industrial, and commercial properties.

We Turn Every Project Into A Hive Of Excellence

-

Masterful Craftsmanship

Our skilled team merges art with function to ensure every roof is a testament to expert craftsmanship and quality.

-

Fast & Efficient

Time is of the essence, and we value yours. Count on our prompt and efficient service for all your roofing needs.

-

Guaranteed Satisfaction

Happiness is our benchmark. Experience peace of mind with our 100% Satisfaction Guarantee on every project.

Our mission at Bumble Roofing is to set new standards in quality by ensuring clients receive top-tier service, world-class materials, and an enduring roof over their heads.